The History of Sewing on Boats

The history of sewing on boats - Marine Fabrication

Sewing canvas onto boats has been an essential practice throughout maritime history. It was a technique used to protect the vessels from the harsh conditions of the sea, and it allowed sailors to travel further and more safely. The practice of sewing canvas onto boats dates back to the 18th century, when canvas was the primary material used for sails and boat covers.

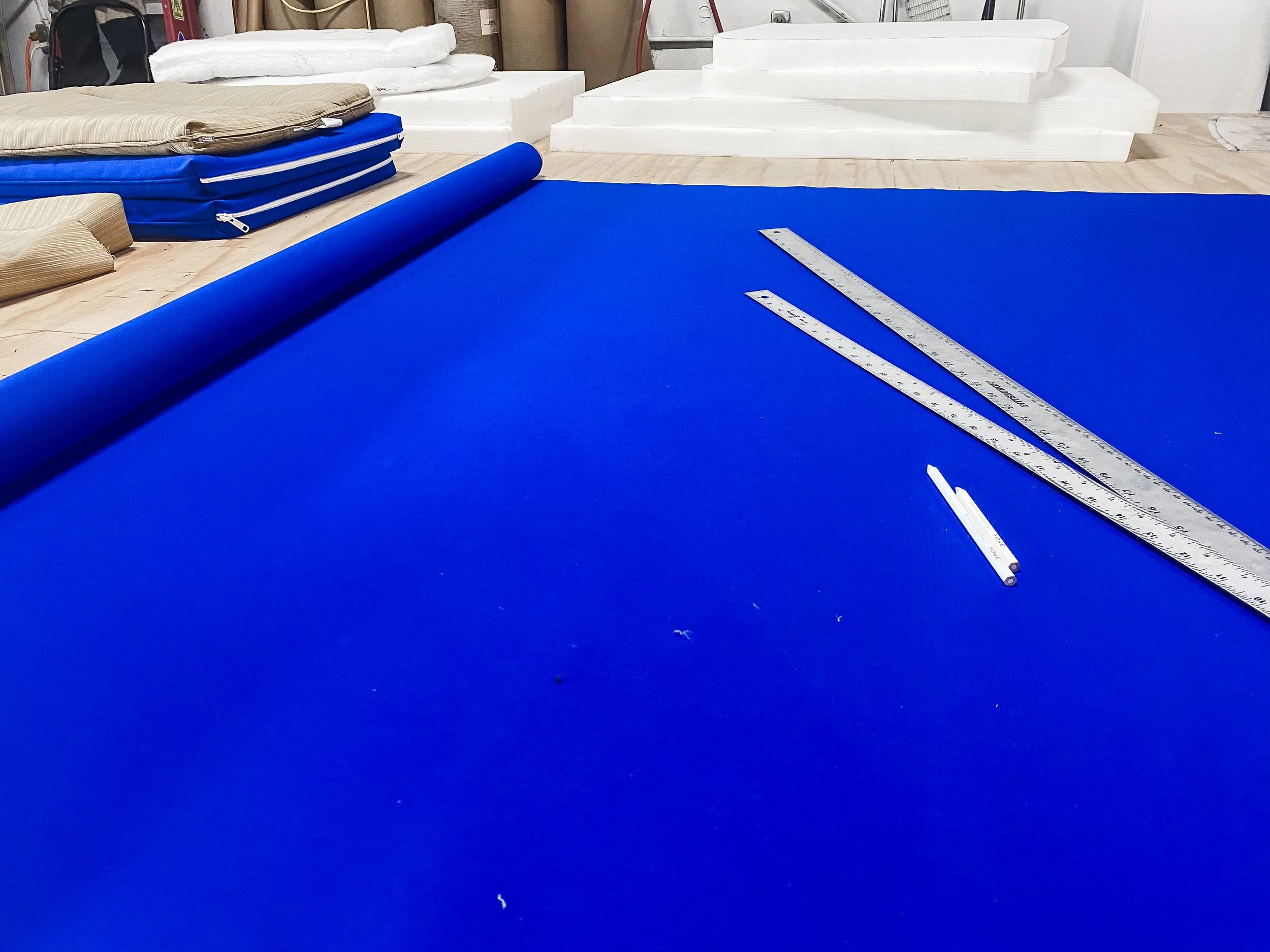

Canvas is a durable and sturdy material that can withstand the salty water and strong winds that boats encounter at sea. When treated with special oils and chemicals, canvas becomes even more water-resistant and can protect boats from rain and moisture. Sailors used to spend weeks sewing together canvas panels to create large covers that could be draped over the entire boat, protecting it from the elements. Today, canvas is still used to cover boats, but it is also used for a variety of other purposes, such as making bags, backpacks, and outdoor furniture. Sewing canvas requires skill and patience, but the end result is a strong and reliable product that can last for years.

At first, sailors used hand-sewing techniques to apply the canvas to the boats. Each stitch was made by hand, and it was a time-consuming process. However, as the demand for faster and more efficient boats grew, so did the need for a quicker way to sew canvas onto them. In response, sewing machines were developed specifically for the purpose of sewing canvas onto boats.

These specialized sewing machines allowed for much faster production of sails and canvas covers. They used heavy-duty needles and thread to stitch through multiple layers of thick canvas material. With the use of sewing machines, boats could be outfitted with new sails and covers in a fraction of the time it took with hand-sewing techniques. This advancement in technology revolutionized the boating industry and allowed sailors to travel further and faster than ever before. Today, sewing machines continue to be an essential tool for the production of sails and canvas covers, with modern machines capable of even more advanced stitching techniques.

The use of sewing machines allowed for faster and more precise stitching, and it also made it possible to add more intricate designs to the canvas. Today, sewing canvas onto boats is still an important practice, and it is done using both hand-sewing techniques and sewing machines. Whether it's for sail covers, dodgers, or biminis, the art of sewing canvas onto boats continues to be an essential part of the maritime industry.

One important aspect of sewing canvas onto boats is selecting the right thread. It's important to use a thread that is strong enough to withstand the harsh marine environment, including exposure to saltwater, sun, and wind. Polyester and nylon are two popular choices for thread materials, as they are both durable and resistant to UV rays. Additionally, it's important to choose the right needle for the job. For example, a sharp needle is best for sewing through thicker canvas, while a ballpoint needle is better for working with more delicate fabrics. By selecting the right materials and tools for the job, boat canvas can be sewn together to create durable and functional covers and enclosures that can withstand the rigors of life at sea.